SO-G Tech’s

UI System

Accessible from any device

Designed with the user in mind, the control centre can be accessed from any smartphone, tablet, or PC via Wi-Fi or local network. The intuitive interface allows seamless monitoring and management of up to six reactors simultaneously, all from a single connected device.

Light and growth automation

The intelligent light-active system continuously monitors and adjusts illumination levels in real time to match the culture’s growth rate. This ensures optimal light delivery throughout every growth stage, maintaining ideal exposure even as biomass density increases.

Full data logging

All system data can be seamlessly exported to your device via secure wireless connection, ensuring effortless reporting and analysis. The unit also features built-in local storage for rapid data access and high-speed downloads, even when operating offline.

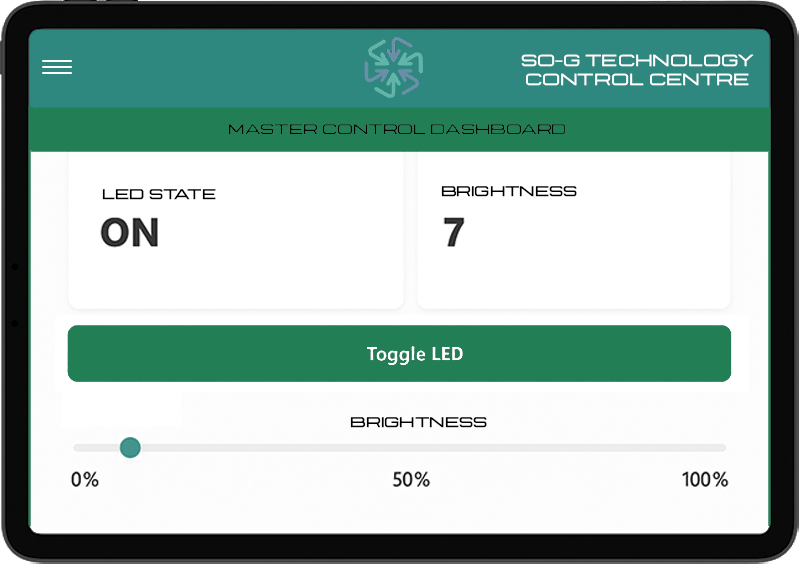

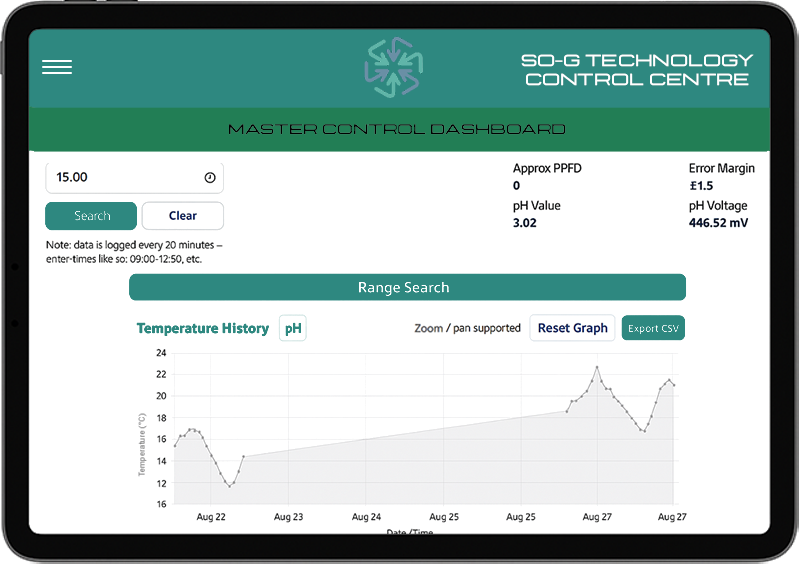

The SO-G Tech App Interface is designed for precision control and effortless monitoring of your bioreactor systems. From a single dashboard, users can view real-time data including LED status, brightness, temperature, pH value, voltage, and light intensity (Lux and PPFD). Adjustable sliders, toggle switches, and calibration tools give you complete command, whether you’re setting brightness levels, syncing operation times, or fine-tuning pH calibration. With manual and automatic modes, built-in error margin tracking, and data logging, the app ensures seamless, closed-loop light and environmental control for optimal algae growth. Intuitive and responsive, the interface empowers researchers to monitor, adjust, and refine every parameter with confidence and precision.

FAQ’s

-

The standard Photobioreactor comes equipped with light, temperature, and pH sensors. Additional sensors can be added upon request for an extra cost.

-

You can easily fill and empty the machine using the pipe located at the bottom of the Photobioreactor, which is controlled by a valve.

-

Photobioreactors can be utilised for various applications, including reducing carbon emissions, researching bio-based products such as biofuels and bioplastics, and serving multiple scientific and industrial purposes.

If you’d like to confirm whether your intended use is compatible, please get in touch with us, we’re happy to help. -

Yes, our Photobioreactors can be controlled from any device with internet access, including your phone, tablet, or computer. You can monitor and adjust all key parameters remotely through a secure online interface.

-

Of course! The Photobioreactor supports the cultivation of marine, freshwater, and brackish water algal species, making it suitable for a wide range of research and production applications.

-

Accidents happen! Each system comes with spare tubes, allowing you to replace a broken one easily. If you need additional parts, contact us and we’ll send replacements quickly.

-

Yes, temperature and CO₂ input can be precisely controlled and monitored, allowing you to maintain optimal growth conditions for your algae species.

-

We provide ongoing technical support, spare parts, and maintenance advice. You can reach us by email or phone for quick assistance whenever needed.